Welding Inspector Can Be Fun For Anyone

Table of ContentsRumored Buzz on Asme InspectionAws Cwi Certification - An OverviewFacts About Certified Welding Inspector UncoveredLittle Known Questions About Certified Welding Inspector.The Basic Principles Of Asme Inspection

Frequently times, a welding examiner may be servicing sky-rises as well as various other structures that are high off the ground, which implies that an examiner shouldn't have a worry of elevations. A welding examiner has a clear understanding of welding strategies, and also apart from evaluating, must have the ability to weld and also examine metal examples for ideal welding techniques as well as procedures.Correct communication is even more crucial given the safety and security and seriousness of the problems a welding assessor is in charge of. Over all, a welding assessor must have qualification to execute examinations in a certain field. Not only does this help make sure that the welder is current on correct procedures and also regulations, however it is something most, otherwise all, companies require.

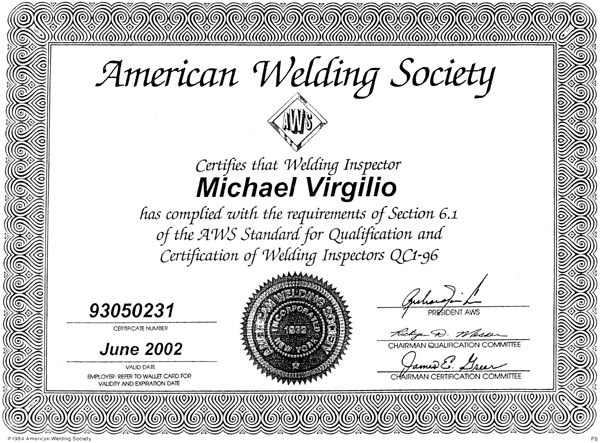

Generally, welding experience counts as one of the most crucial ability when obtaining certified for an examination job. Certified Welding Inspector. Depending upon the certification he obtains, a welding examiner may operate in a number of various locations. One of the organizations that supplies qualification in the United States is the American Welding Society, which certifies welders to do examinations on structures, such as structures and dams.

Each company has its own codes the inspector needs to comply with, which are called the Welding Treatment Specs (WPS).

6 Easy Facts About Cwi Certification Explained

Senior Staff Designer, National Board This article was initially released in the Autumn 2009 National Board NOTICE as the very first of a two-part collection. Keep in mind: The purpose of this short article is to offer inspectors with a basic expertise of weld assessment.

Weld assessment begins long before the very first welding arc is struck. The examiner should assess the work package to become acquainted with the: welding processes to be utilized; products and any type of unique properties; joint configurations as well as preparation; welding procedure specifications to be utilized and any kind of constraints; qualifications of welders to be used and also any restrictions; warm therapy (pre-heat or postweld), if any type of; nondestructive assessment (NDE), if any; and also particular ASME Code or NBIC demands (for example, Area VIII, Div.

While not critical, the assessor ought to learn to check out common weld signs such as the AWS signs. At the very least, the examiner needs to always lug a referral guide to analyze weld signs. Having actually evaluated all this details beforehand, the assessor will certainly be prepared to identify any problems as they develop instead of after-the-fact.

The manufacturer or repair service company (certificate holder) has suggested on the work attracting that a weld joint is to be prepared with a 60-degree bevel as well as origin space of 1/16 inch. Unless the bevels are crushed on accuracy equipment, it is skeptical they will certainly accomplish a precise 60-degree bevel as shown.

The 5-Second Trick For Aws Cwi Certification

Offering an and also or minus resistance will certainly make the welder's work a lot simpler. The examiner can make use of scraps of weld filler cable or rods as a gauge to promptly determine root voids that are past the resistance variety.

Also a 1/8-inch wire needs to display no side-to-side movement throughout the void. Real globe scenarios are seldom this convenient, yet the assessor can establish a sense of "also limited" or "too loosened" with experience. The certificate holder has actually developed a straightforward nozzle to be bonded to a flat head (Fig.

The nozzle axis is 90 to the flat head, and also the attachment weld consists of a 3/8-inch fillet weld. The inspector can conveniently determine the fillet weld to make sure conformity. Now, let's mount the same nozzle in a little size vessel shell (Fig - AWS CWI Certification. 2). The fillet weld will have a tendency to spread or squash on opposite sides of the nozzle due to the curvature of the covering.

This instance becomes much more vital if the nozzle is set up at an angle besides 90 (Fig. Welding Inspection Certification. 3). Utilizing the same nozzle accessory example as explained above, let's take a look at the weld joint prep work. The certificate owner has defined a 45-degree bevel around the circumference of the opening in the flat head and also the vessel shell.

Little Known Facts About Aws Cwi Certification.

4). The curved look at this web-site covering will offer more of an obstacle. The inspector will certainly need to establish if the certificate owner is referencing the bevel from the vertical axis of the nozzle (Fig. 5) or from the variable referral plane of the rounded covering (Fig. 6). When bevels are prepared with a cutting torch as well as do with a mill, it is extremely difficult to preserve a specific angle. AWS CWI Certification.

Exactly how does the inspector make sure conformity with the code? Examiners are trained to think only what their eyes tell them; yet when the examiner can not see the inner surface of television, it comes to be hard to approve that scenario. This is when the assessor needs to take what some would call a "jump of belief." If television ends are appropriately prepared (beveled) and also a qualified welder is using a certified welding treatment, the odds are excellent that the welds will certainly be complete infiltration.

One "red flag" to a prospective trouble would certainly be if the examiner observes that the tube ends have actually not been beveled. The assessor should promptly ask the certificate owner regarding this circumstance. Maybe as straightforward as the certification owner having actually simply not done that step in the procedure yet, or it can be as poor as his/her having actually tried to save money and time by not beveling completions.

The Basic Principles Of Structural Steel Inspector

The welder would certainly need to start with a large origin void and then be really careful not to "press through" excess filler metal to cause weld build-up on the within the tube.